Lock or hard point on drawer slides? You have opted for a telescopic slide, perhaps by following the steps in our blog article dedicated to this subject: “Selecting the perfect telescopic slide in 5 steps”.

Now you want to block your sliding drawer! But which solution should you choose?

- A manual lock,

- a slam lock handle

- a hard point

CHAMBRELAN has written for you, this guide with our locking systems and explains which one is the most adapted to your telescopic slide!

Contents :

1- Locking :

A – Different types of manual locks :

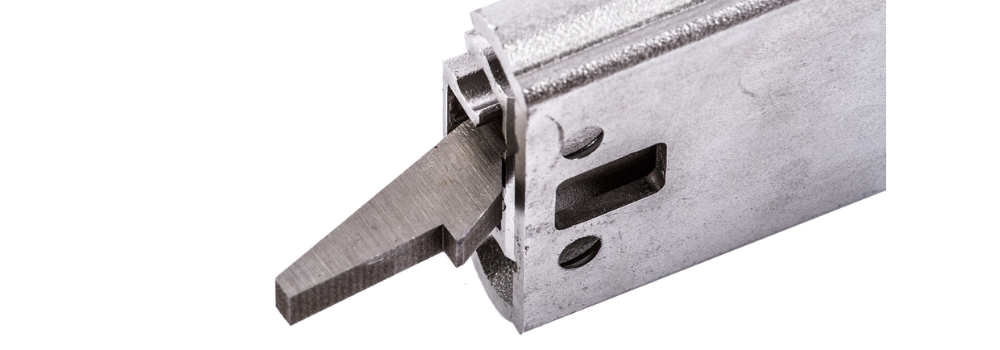

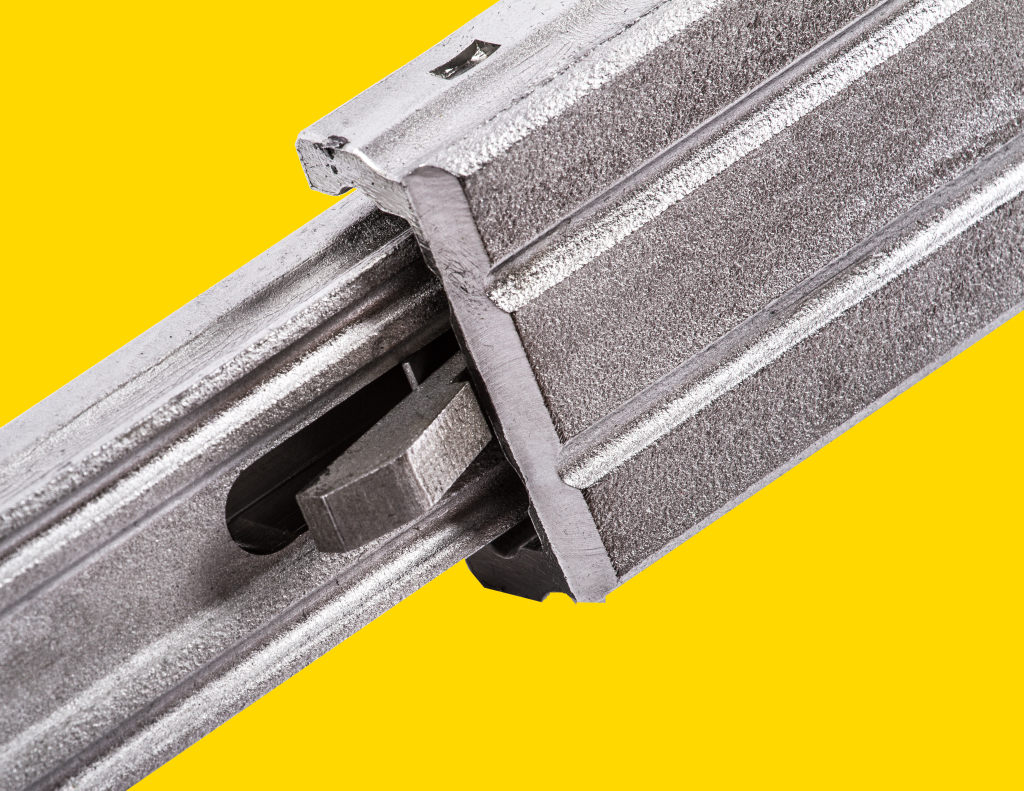

The locking device proposed by CHAMBRELAN is an option on some models. It allows to LOCK the drawer slide. A manual action on the latch, located on the mobile part of the slide, is necessary to move the drawer.

These different locks are options to be inserted when manufacturing our telescopic slides. Do not hesitate to specify your project by contacting us directly!

CHAMBRELAN has designed three types of manual locks.

-

- in open position (deployed),

When your sliding drawer is open, it is blocked and cannot be folded back. Only a manual unlocking will be able to close it again. The user will have to press on a latch positioned on the slide to fold the drawer.

-

- closed (retracted)

In this case, the drawer is locked in the closed/folded position. The user will have to operate the lock on the telescopic slide to unlock it and open the drawer.

Please note that you must provide access to operate the lock !

-

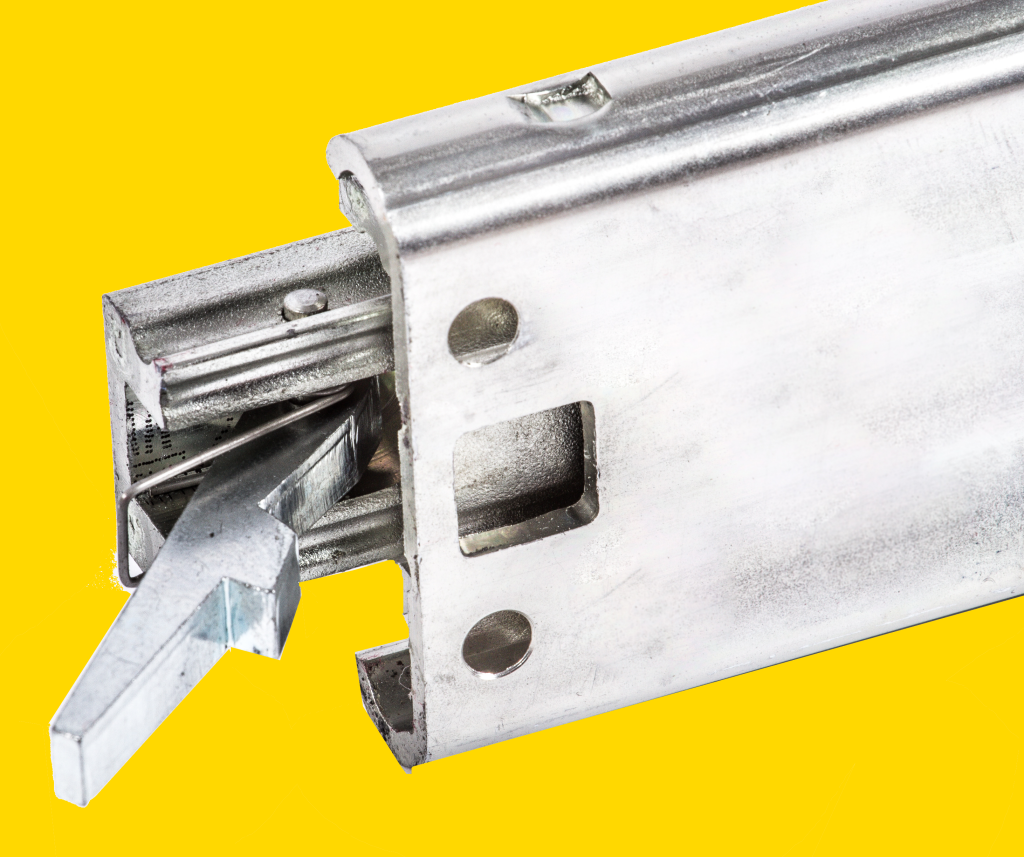

- or a combination of both!

Combining these two locks is possible! For more security, it is possible to block your drawer both when it is closed and when it is open! As in the previous cases, user action is required to move the installation!

For more details about these different types of locks, we invite you to browse our blog article: “Locking on sliding drawer”.

Please note, that for mounting a pull-out drawer, it is not necessary to install a lock on both slides! A lock on one of the two slides will suffice to lock the drawer!

2- Slam lock Handles :

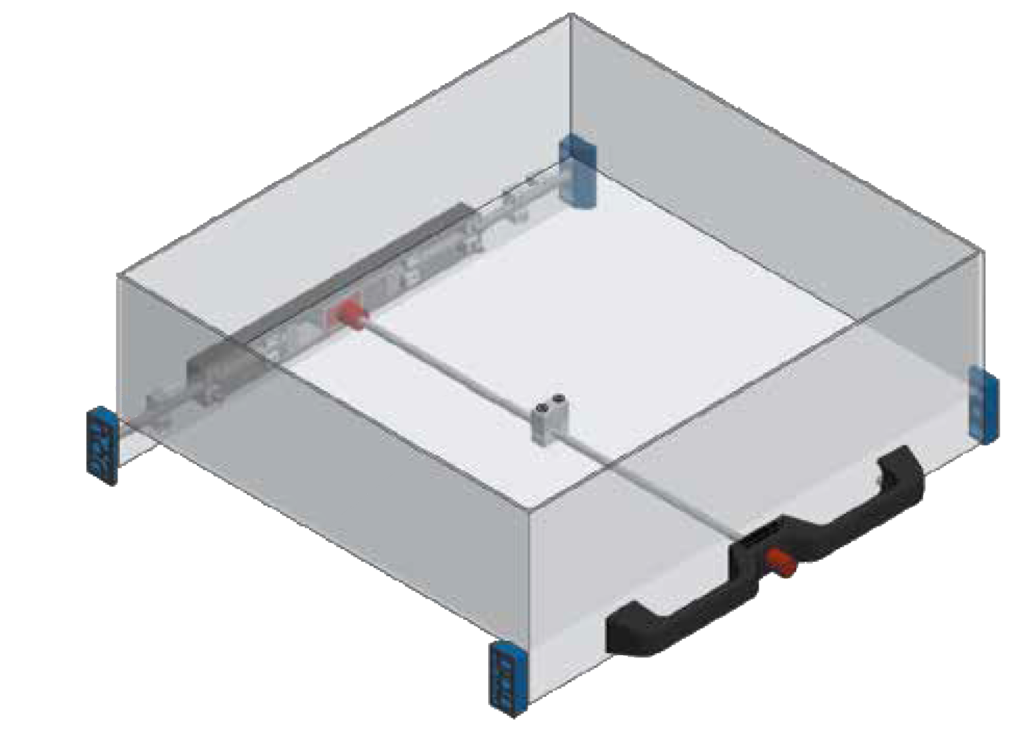

Sometimes, in some projects, it is more practical (or sometimes even obligatory) to install a slam lock handle directly on the sliding drawer or the protective cover of a machine.

In fact, the slam lock handle is proposed on an installation with a telescopic rail as well as a guide rail, both horizontally and vertically! Ergonomically designed, it can be operated by both right- and left-handed users!

3 slam lock handle are once again proposed by CHAMRELAN :

Ergonomic slam lock Handle :

Ideal to lock a sliding system in folded position! The user will only have to unlock the drawer by pressing the button positioned in the center of the handle! One finger is enough to open the system! Appreciated in emergency vehicles, because it is easy to use and ergonomic, this slam lock handle provides safety and reliability for the driver and passengers!

Ergonomic double slam lock handle:

Just like the lock in open and closed position to be installed on telescopic slide, this slam lock handle can block your drawer when it is open and closed! Again, the user can open and close this drawer by pressing the central button of the handle! You can find this locking system on the machine covers, positioned vertically, to keep the housing locked when it is opened or closed! Anyone can use this handle, even with protective gloves!

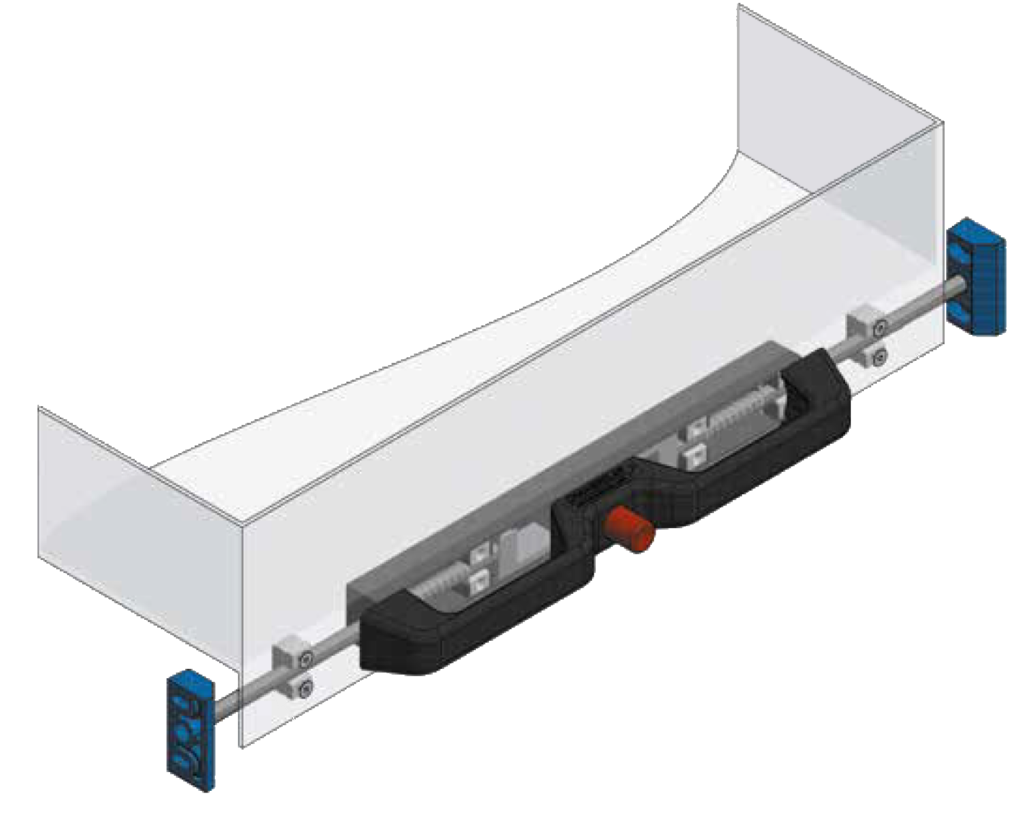

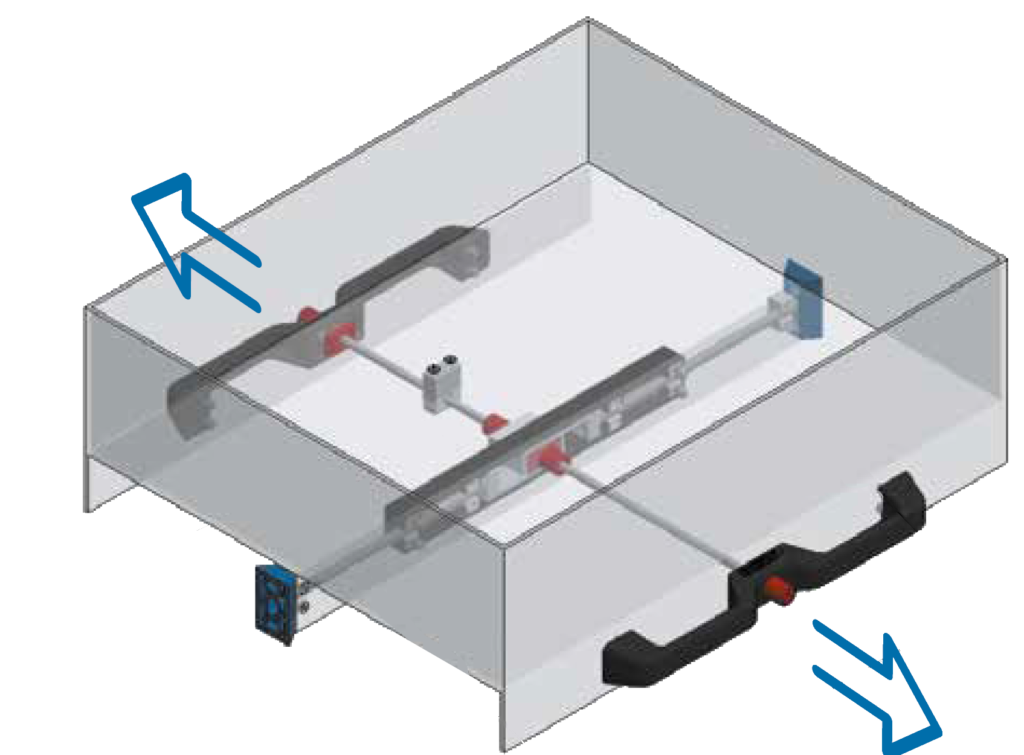

Ergonomic Slam lock Handle for double extension:

For mounting lines, for sliding drawers in clean rooms or all installations requiring a bilateral opening, we recommend the installation of a double extension telescopic slide.

In order to lock these sliding systems in a central position, we propose the Ergonomic Slam lock Handle for double extension!

Thus, the drawer locks in the center and a simple action is enough to unlock the installation by pressing the handle button!

The system is delivered complete with 2 control handles.

For more information on double extension systems, please refer to our dedicated article: “Designing a double extension drawer »

3 -Hard point :

The hard point, is a restraint in closed or open position of the telescopic slide. Contrary to the locking, manual or by slam lock handle, no action on a mechanical latch is necessary. Opening or closing is done by pulling harder on the drawer.

This option is very technical because it must be adapted to each type of mounting: retaining 5 kg is not the same as retaining only 20 kg. A study is therefore generally necessary, which will only be justified for large quantities.

It does not exist on drawer slides for loads over 80 kg.

It is strongly discouraged in vehicles or mobile systems.

It exists in the same condition as a locking system, : open hard point, hard point when folded, open and closed hard point.

On some models with partial extension, such as R53, R71 or R91, we can propose a closed hard point by magnetization.

Please note that hard point is an option on some telescopic slides, please contact us for more information!

4- What needs to do these options meet?

Manual locks :

Manual locks usually meet the following needs:

-

-

- They exist only on telescopic slides,

- For heavy load sliding drawers,

- In an industrial environment,

- Outdoors,

-

Slam lock Handle :

The main advantage of these Slam lock handles is that they are ergonomic and quick to access and use; They can be installed in most mounting conditions:

-

-

- Utility and emergency vehicles (preferable to manual locks that are not resistant to vibrations),

- Clean rooms or laboratories,

- Vertical sliding panel,

- On sliding door

- Bilateral sliding system

- System with indexing (especially vertical)

- with Linear Rails

- On SLIDE TILT kit

-

Hard points :

They are implanted on light devices up to a few tens of kilos maximum for any system requiring a simple blocking and not a locking :

-

-

- Tray for computer keyboard

- Desk drawer

- Industrial or medical workstation

-

5 – Summary

|

LOCK |

SLAM LOCK HANDLE |

HARD POINT |

|

|

POSITION |

|||

|

OPEN ONLY |

√ |

X |

√ |

|

CLOSED ONLY |

√ |

√ |

√ |

|

OPEN AND CLOSED |

√ |

√ |

√ |

|

BILATERAL OPENING |

X |

√ |

X |

|

TYPES OF LOCKS |

BY INTERNAL LATCH

|

PER BUTTON AND HANDLE

|

BY LOCKING AND HOLDING

|

|

NEEDS AND ENVIRONMENTS |

INDUSTRIAL

OUTSIDE TRAY AND SLIDING DRAWER HEAVY LOADS |

CLEAN ROOMS

SLIDING DOORS VERTICAL MOUNTING VEHICLE AND EMERGENCY VEHICLES MACHINE PROTECTION HOODS BILATERAL SLIDING SYSTEMS INDEXING TILTING DRAWERS |

SLIDING DRAWING of low load

KEYBOARD WORKSTATION |