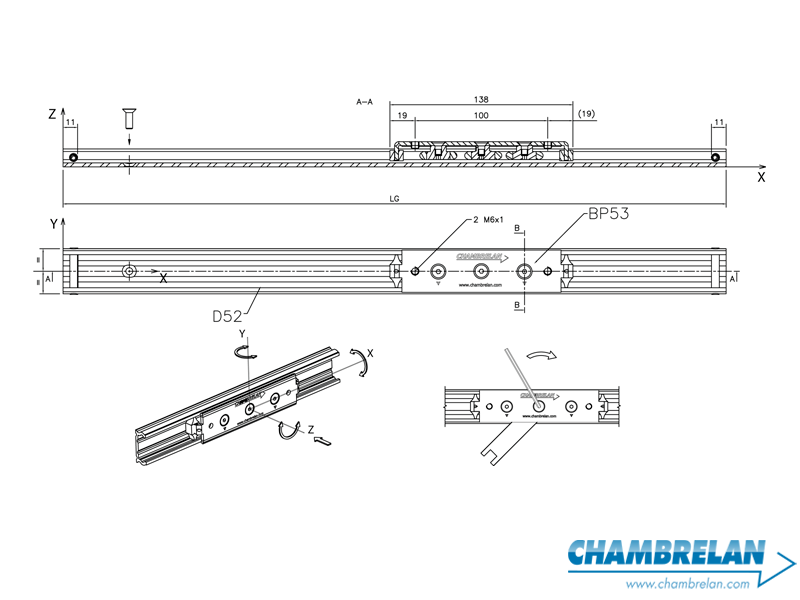

Sliding rail for door - Aluminium - Roller runners

D52-BP53

This D52 colourless anodised aluminium guide rail is fitted with one or more BP53 roller runners. The rollers are made of stainless steel and are lubricated for life and sealed.

3D download:

Sorry, no 3D meets your criteria. Please choose a different combination

Table of lengths

Applications

This linear guide rail is designed for medium loads in applications requiring a very small footprint, such as small covers or housings for machine protection.

Recommended operating temperatures are -20 to 100°C.

Avoid installing these guides in applications subject to severe vibration. Please consult us.

This type of product does not withstand torque loads well, so ensure that the load is balanced under one or more pads, if necessary.

This product can be used as a translational guide, a guide bar or rod, a suspended rail, a handling rail, a door rail, a horizontal guide or a vertical guide such as a guillotine type guide.

Manufacturing

Chambrelan manufactures this guide rail on the basis of extruded aluminium profiles.

The rail is supplied as standard with a colourless anodised protection.

The rail is equipped with rubber pin stops at both ends. Adjustment of runners :

The rail and runner system is delivered assembled with minimal play and optimal running properties.

We deliver the runner and rail system assembled and therefore pre-set. If a runner is delivered separately, or if it has to be mounted in another rail, or if you have non-standard operating requirements, an adjustment can be made. Please note that a correct adjustment of the runner is essential for the life of the system.

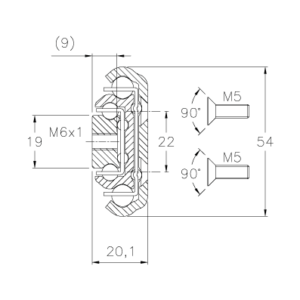

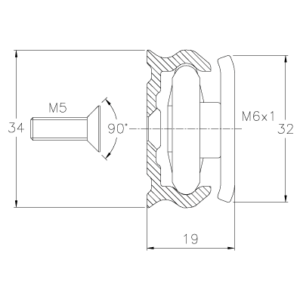

After checking the cleanliness of the tracks, insert the runner without wiper into the rail

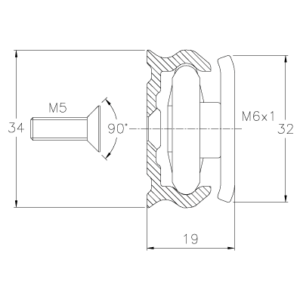

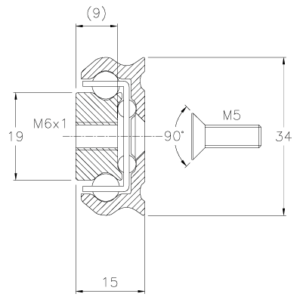

– Loosen the adjustment screw of the central roller which is mounted on the eccentric,

– With the rail on edge, turn with the key supplied to obtain the desired setting, then tighten the fixing screw to the torque recommended on the data sheet.

– Check that the runner slides in the rail. The runner should move freely without excessive play.

– Refit the wipers.

Chambrelan specialises in the design and manufacture of telescopic ball bearing slides and guide rails for industrial applications: reinforced slides, linear slides, ball bearing guides, rolling guides, metal runners in steel, aluminium, stainless steel with locking, blocking and in full extension, partial extension, double stroke or super extension for heavy duty industrial drawers, mechanical panels.

Maintenance

As standard, our slides are delivered lightly greased from the factory. We use a high pressure bearing grease for steel slides, and a white grease for aluminium and stainless steel slides. On request, we can use a food grade grease (clean room compatible), a high temperature grease, a teflon free grease (paint booths) or a greaseless assembly (although we do not recommend this).

A food grade grease, combined with stainless steel balls, offers an economical alternative to all stainless steel slides.

Options

Manual locking system

There is no internal locking option at this time.

Surface treatments

This slide can be supplied with a hard anodised surface protection. This option can be justified for applications subject to vibration.

High temperature use (oven type)

We do not recommend the use of this product outside the recommended temperature range.

Modification of the standard

– Customised lengths

– Customised drilling pattern

– Other surface treatments (corrosion, hardness)

– Vertical mounting (guillotine type)