Stainless Steel Sliding Track

Sliding rails are essential for the design of industrial machinery. This type of machinery requires many requirements both in terms of assembly and the materials used to manufacture it. Chambrelan is specialised and recognised in the manufacture of professional linear guide systems. A wide range of references is available to meet all your needs, we also offer aluminum sliding tracks and steel sliding tracks.

Filters

1. Our stainless steel sliding rail models

Chambrelan offers two types of sliding stainless steel rail models. First of all, it is important to choose the right length for your project. Once you have made your choice, you should choose between stainless steel rails with runners or rollers. What are their specificities ?

Rail with ball bearing pads

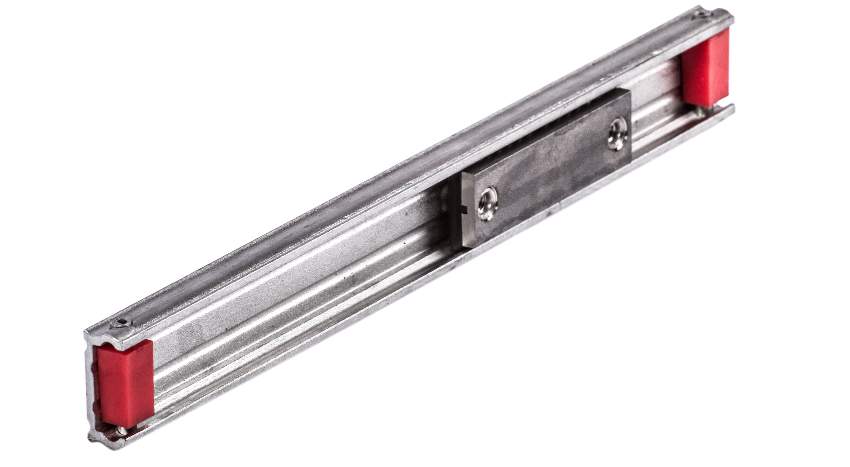

Stainless steel runner rails are designed to slide in a fixed rail. Made from cold drawn stainless steel, they can withstand heavy loads and are perfectly suited to the industrial sector. Several models with runners are available such as the ST53-GS53 or the ST50-GS52. These sliding stainless steel rails are adaptable: length, number of runners, etc.

Each model has its own specific features, particularly with regard to the loads supported and the options available, such as the wiper seal, which is designed to protect the balls. The rails are equipped with pinned stops and are delivered after an electrolytic passivation as well as the pads.

Rails with roller runners

Stainless steel roller tracks consist of a linear track and a roller pad. Ideal for the medical or food sector, this system has the advantage of being silent and supports loads of up to 100 kg per skid.

Among our models, Chambrelan offers the ST53-BP53 (plastic coated rollers) and the ST53-BS53 (all stainless steel rollers), these stainless steel slide rails can withstand medium loads and temperatures from -20/-4 °F to 80°C/212 °F.

2. Stainless steel sliding rails, simple and quick to maintain

Our products are always delivered greased to protect them and withstand repetitive handling.

There are different types of grease to choose from:

- high pressure bearing grease for steel slides

- white grease for aluminium and stainless steel slides

- food grade grease (clean room compatible)

- high temperature grease

- Teflon-free grease (paint booths)

- no greasing

Depending on the frequency of use of stainless steel rails and the environment in which they are installed, maintenance will have to be more or less recurrent. However, Chambrelan designs rails that require little maintenance.