Telescopic drawer runner - Steel - Locked - Super Extension

RA554MF

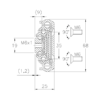

Steel reinforced and synchronised telescopic slide with super-extension. It includes a lock IN: when the drawer is in the closed position, a lock has to be pushed to open the slide. Heavy duty.

×

3D download:

Sorry, no 3D meets your criteria. Please choose a different combination

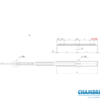

Table of lengths

The characteristics given on this website correspond to standard manufacture or usual requirements. Our position as a manufacturer enables us to offer great flexibility in order to meet the most specific requirements.

Applications

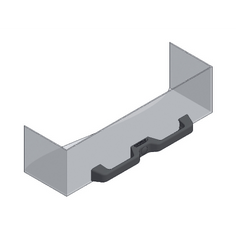

This guide runner is very resistant, both in terms of its cold-drawn profiles and its operating stops. It is designed for heavy-duty drawer applications or for heavy-duty use. As it is equipped with reinforcing balls, it can also be mounted flat. Remember that flat mounting results in a large deflection. Increase the spacing between the elements by using shims not supplied to avoid friction due to the deflection.

Recommended operating temperatures are -20 to 80°C. After adaptation in the factory, we can go from -50 to 250°C

This product can be used as a telescopic leg, battery drawer ...

This guide runner is very resistant, both in terms of its cold-drawn profiles and its operating stops. It is designed for heavy-duty drawer applications or for heavy-duty use. As it is equipped with reinforcing balls, it can also be mounted flat. Remember that flat mounting results in a large deflection. Increase the spacing between the elements by using shims not supplied to avoid friction due to the deflection.

Recommended operating temperatures are -20 to 80°C. After adaptation in the factory, we can go from -50 to 250°C

This product can be used as a telescopic leg, battery drawer runner, furniture runner, telescopic walkway guide, heavy duty bar or rod, tool cabinet or workshop telescopic table runner, hanging rail, translational guide, heavy duty drawer runner, horizontal guide.

Manufacturing

Chambrelan manufactures this slide on the basis of cold drawn steel profiles.

It is supplied as standard with a white zinc coating, with an average thickness of 12 microns, which offers excellent resistance to salt spray tests.

It is equipped with free stops on opening and closing.

It has zinc-plated steel ball cages.

The balls are made of 100C6 chrome steel. It is lubricated with standard bearing grease.

Chambrelan specialises in the design and manufacture of telescopic ball bearing slides and guide rails for industrial applications: reinforced slides, linear slides, ball bearing guides, ...

Chambrelan manufactures this slide on the basis of cold drawn steel profiles.

It is supplied as standard with a white zinc coating, with an average thickness of 12 microns, which offers excellent resistance to salt spray tests.

It is equipped with free stops on opening and closing.

It has zinc-plated steel ball cages.

The balls are made of 100C6 chrome steel. It is lubricated with standard bearing grease.

Chambrelan specialises in the design and manufacture of telescopic ball bearing slides and guide rails for industrial applications: reinforced slides, linear slides, ball bearing guides, metal runners in steel, aluminium, stainless steel with locking, blocking and full extension, partial extension, double stroke or super extension for heavy duty industrial drawers, mechanical panels.

Maintenance

As standard, our slides are delivered lightly greased from the factory. We use a high pressure bearing grease for steel slides, and a white grease for aluminium and stainless steel slides. On request, we can use a food grade grease (clean room compatible), a high temperature grease, a teflon free grease (paint booths) or a greaseless assembly (although we do not recommend this). A food grade grease, combined with stainless steel balls, offers an economical alternative to all stainless steel slides.Options

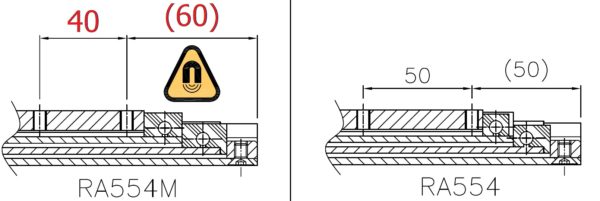

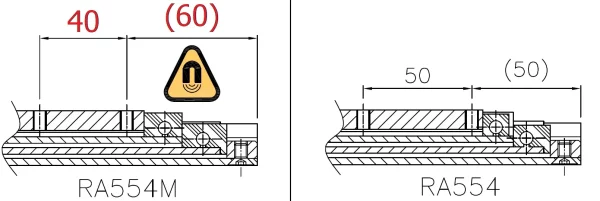

Manual locking system

Lock open: when extended, press the lock to fold it up.

Locking closed: when folded, the lock must be operated to unfold.

Locking open and closed: when folded, the lock must be operated to unfold and when extended, the lock must be pressed to fold.

In most cases, only a latch slide is used to lock the entire drawer. This makes assembly and operation easier.

If you are installing in vehicles, please consult us if you plan to use locking slides.

The presence of locks makes certain short lengths impossible to manufacture. In addition, some standard drillings may not ...

Manual locking system

Lock open: when extended, press the lock to fold it up.

Locking closed: when folded, the lock must be operated to unfold.

Locking open and closed: when folded, the lock must be operated to unfold and when extended, the lock must be pressed to fold.

In most cases, only a latch slide is used to lock the entire drawer. This makes assembly and operation easier.

If you are installing in vehicles, please consult us if you plan to use locking slides.

The presence of locks makes certain short lengths impossible to manufacture. In addition, some standard drillings may not be possible.

We do not recommend the use of locks for vertical installation (sash type).

Surface treatments

Other surface treatments are also possible to increase the strength of the slide. Please consult us.

Nitriding is also possible in order to increase the life of the slide in case of intensive use, or to make it more resistant to matting in case of intense vibrations.

Mounting with stainless steel balls

It can be mounted with stainless steel balls to achieve very good corrosion resistance, which in some cases can offer an economical alternative to stainless steel slides.

High temperature use (oven type)

This model can be used in high temperature environments up to 250°C. However, some adaptations are necessary:

- freedom of assembly to allow expansion of the elements without blocking the slide,

- use high temperature lubrication

- remove all plastic elements.

These adaptations to the slides must be made in the factory. It is therefore important to inform us when requesting a quotation and to allow for a manufacturing time.

Zinc plating deteriorates from 120°C, we can offer you other solutions.

Modification of the standard

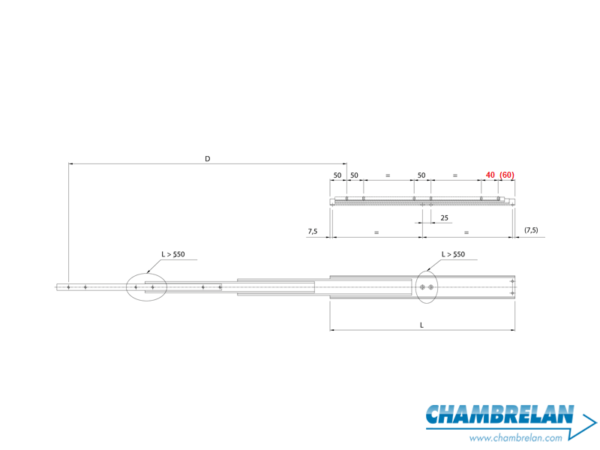

Development: This model can be increased by 10% or decreased.

An increase in development reduces the maximum permissible load.

Custom lengths and strokes.

Customised drilling pattern

Other surface treatments (corrosion, hardness)

Vertical mounting (guillotine type)