This white paper explains most of what you might need to know about a industrial drawer slide.

- Why a telescopic slide?

- What is a drawer slide?

- What are the different extension ?

- How to choose a telescopic slide?

- What are some possible customisations of an industrial slide?

- Some examples of heavy duty slides use ?

- Contact us for more information!

1 – Why a Telescopic Slide?

What is a telescopic slide?

A drawer slide is also known as slide, support rail, sliding rail, ball bearing slide, telescopic slide, telescopic guide, telescopic rails, bearing guide, slide system, ball bearing rail, industrial slides…

What is the purpose of a telescopic slide?

A telescopic slide is mostly used to extract a load.

Industrial slides and sliding rails are not limited to one use. They can be used as a drawer slide, hanging rail, door slide, keyboard drawer, handling rail, furniture slide, telescopic table slide, horizontal guide or in some cases, as a vertical guide for a door or as a machine tool guard guide.

Why choose a CHAMBRELAN telescopic slide?

CHAMBRELAN, experienced manufacturer of professional slides and sliding rails since 1956, offers a wide range of products with many options and adaptations that meet requirements and technical constraintqs.

Specialized in industrial slides, CHAMBRELAN designs, produces and tests its slides in order to provide a solid and reliable ready-to-use guides. With its 60 years of experience, CHAMBRELAN offers technical advices that match the end-user needs.

2 – What is a telescopic slide?

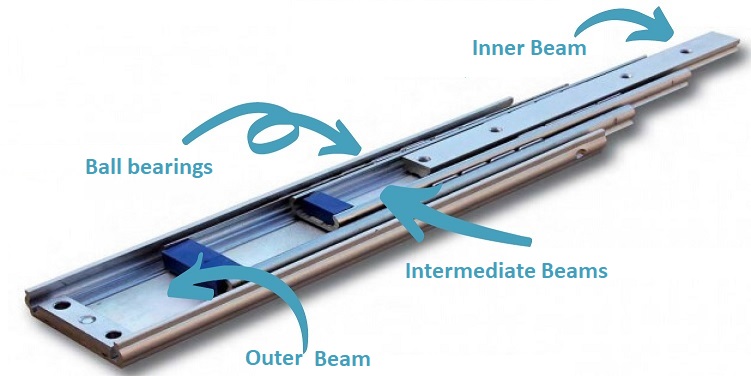

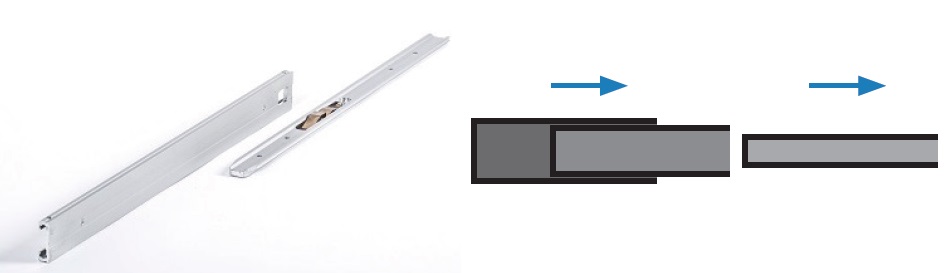

A telescopic slide is an assembly of metal profiles sliding on ball bearings held in ball cages.

It is equipped with stops on opening and closing, and ensures the sliding of loads up to several tons.

Here are the details of the components of an industrial “C” slide:

– The fixed part is called the “outer beam”.

– The mobile part fixed on the drawer is called “inner beam”.

– The part ensuring the additional extension is called “intermediate beam” (up to 2 beams).

For a high performance “I” shaped slide:

– Each flat beam is called a “inner beam”, one being fixed and the other mobile

– The central I is the intermediate beam (not the fixed part!)

CHAMBRELAN offers them in sizes from 150 mm (6 in) to 2 meters (6 1/2 ft) and for loads up to 1.5 tons (3300 lbs). Available in steel, aluminium or stainless steel, CHAMBRELAN telescopic ball bearing slides allow partial, total or super-extension.

CHAMBRELAN slides include stoppers are dimensioned according to the admissible load at a maximum operating speed of 0.3 m/s. As simple as it may be to manufacture profiles that can support a high load, the design of the stops can be a crucial point for the reliability of the system and the safety of use..

3 – What are the different extension?

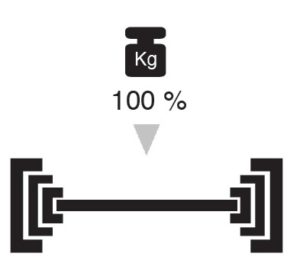

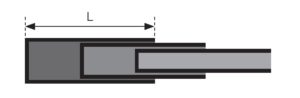

The extension of a slide is related to the extension of the mobile part compared to the fixed part. It is a function of the number of elements in the slide and is measured in relation to the closed length.

– The partial development :

The slide is composed of 2 elements: an outer and an inner beam.

It offers an extension between 60% and 70% of the closed length, a part of the mobile element having to remain inside the fixed element.

– The total development:

The slide is made of 3 beams.

It offers an extension corresponding to 100% of the closed length, with the intermediate beam providing the additional extension.

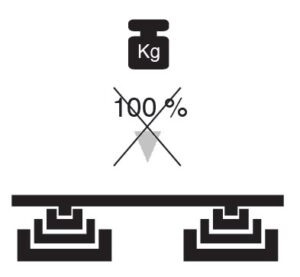

– The super extension

The slide consists of 4 elements: one outer, two intermediate and one inner beam.

It offers an extension corresponding to 150% of the closed length, the two intermediate elements ensuring the over-extension.

CHAMBRELAN standard slides offer extensions from 100 mm – 4 in to 3 metres – 10 ft!

4 – How to choose your telescopic slide?

1 – Choosing the appropriate stroke

Depending on the space available for the slide, which will therefore give the closed length, you can choose the extension, according to 3 main families. Partial extension, total extension or super extension:

Use a partial extension slide if :

– There is limited space in and around the enclosure,

– Limited access is required,

– a safety feature is required: anti-tilt system.

Use a full extension slide if :

– You need 100% deployment,

– This is The model generally used.

Use a super-extension slide if :

– the front side of the drawer is thich or a there’s a drawer setback from the front,

– there’s a need to access The rear of a drawer for maintenance purposes, or for wiring.

As a manufacturer, CHAMBRELAN produces these different types of extensions and is able to customise the standard extension of a slide:

– Under-development : a shorter stroke increases the load capacity and reduces the deflection,

– Over-development : increasing the standard extension will reduce the load capacity.

2 – Choose the appropriate load capacity:

Each drawer slide model is given a maximum load value depending on its closed length and extension.

What is the maximum load of a slide?

This is the maximum load

-

-

- of a pair of slides,

- mounted horizontally,

- on the major axis,

- in the fully extended position (where the slides are subjected to the maximum force).

-

A slide can be mounted :

– on the major axis, which is the recommended mounting direction for optimum use

– flat (or bottom) mounting , which requires the slide to be oversized and will result in increased deflection

The load is given under “normal” operating conditions in terms of

– Assembly tolerances,

– Operating temperatures,

– Number of cycles,

– Operating conditions…

So remember to take into account the specifics points when calculating the weight of the drawer.

Note that any telescopic slide will show a deflection under load when extended: this is the bending of the elements subjected to the load.

Each CHAMBRELAN slide has been designed and simulated in a CAD model; the theoretical results have been validated in the laboratory, according to our assembly recommendations (available in our catalogue or on our website), on a test bench in different load ranges and under operating cycles. Individual variations, such as deflection under load depending on the mounting, are indicated on the data sheets.

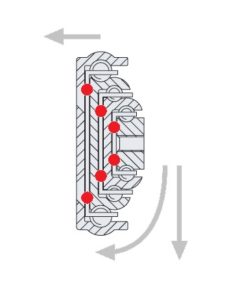

CHAMBRELAN is specialised in the manufacture of heavy duty slides:

– On the one hand with reinforced guides :

Additional “reinforcing” balls limit the torsion of the elements subjected to the load. This development allows a significant increase in the admissible load while reducing the opening and closing forces.

– On the other hand synchronised slides

Sequential opening of the elements, possible on certain 3 or 4 element slides, considerably reduces the opening forces by controlling the opening order of the telescopic slide beams.

Use our Slide Selector to identify the drawer slide that meets your needs!

3 – Which materials and surface treatment?

All CHAMBRELAN slides are supplied with a corrosion protection treatment: White zinc (RoHS/REACH compliant) for steel and colourless anodising for aluminium, which is suitable for most applications. Depending on the material used, there are several possibilities of surface treatment:

1. Carbon steel drawer slides:

The resistance of a treatment is measured in HOURS before more than 5% of the total surface is covered with rust, during a salt spray test in an oven. The data to be taken into account is the resistance to RED rust.

a. Standard zinc plating

Red rust: 400 H

b. High strength zinc plating (optional in BLACK)

Red rust: 600 H

c. Nickel plating (optional in BLACK)

Red rust: 1000 H

d. Carbonitriding

This treatment, similar to nitriding, increases the surface hardness of the material and provides better resistance to vibration therefore increasing the service life. As it has little resistance to corrosion, we recommend that it be combined with zinc plating.

2. Aluminium telescopic slides:

a. Colourless anodising

b. Hard anodising

which is recommended in case of impact or vibrations

3. Stainless steel bearing guides:

They are cleaned and passivated.

Please note: stainless steel slides are not completely non-magnetic although the parts are made of 304L or 316L, materials also used for the balls, which is basically non-magnetic.

4 – What options are available on a telescopic slide?

– Locking :

A mechanical locking device allows the slide to be locked. Manual action on a latch is required for unlocking and operate the drawer.

– in the extended position (open lock),

– retracted (lock closed),

– or a combination of both (lock open and lock closed).

– Synchronisation of the elements on opening:

Sequential opening of the elements, which is possible on some 3-element slides, reduces opening forces by controlling the order in which the elements open.

– Double extensions slides :

A development on each side of the fixed part can be adapted on certain models of slides. Simple to install on 2-part slides, it requires a device on 3-part slides to recenter the intermediate beam.

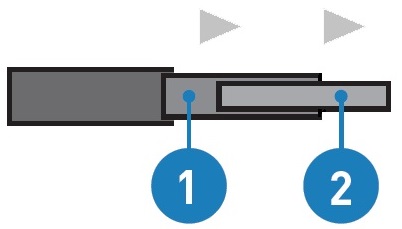

– Detachable sliders:

Detachable is an option on some models that allows the inner element to be removed from the slide and then reinserted on the same slide.

– Vertical mounting (GUILLOTINE):

When using ball bearing slides vertically or at an angle, the ball cages will shift downwards after a few cycles due to gravity, causing a loss of development.

This can be limited by inserting a compensating stamping. It is therefore essential to inform us of the vertical assembly before manufacturing.

In this type of assembly, we recommend the use of linear guide rails.

– Closed hard point

This is a retention in the closed position of the telescopic slide. The drawer is opened by pulling harder (in contrast to locking, no manual action on a latch is required).

A hard point in the closed position can be implemented on some models, either by a mechanical device or by magnetisation.

The difficulty with this device is that it is always too hard when unloaded and barely perceptible under heavy loads. An adaptation to the real conditions of the application is therefore essential.

5 – What are some customisations of a telescopic slide?

Closed lengths :

For standard slides, the usual lengths range from 150 mm – 6 in to 2,000 mm – 7 ft, in 50 mm increments, depending on the reference. This length can be adapted.

Drilling pattern or fixing system:

The positions and diameters of the holes are defined as standard on the data sheets.

They can be customised on request.

Mounting accessories:

Such as angle brackets, bayonet hooks or shoulder screws with collar can be fitted to the slides to simplify assembly or maintenance.

Extension:

Any manufacturer is able to customise the standard extension of a slide:

– By reducing its stroke to increase load capacity or reduce the deflection,

– By increasing the standard extension, but the load capacity is then reduced

Operating temperatures:

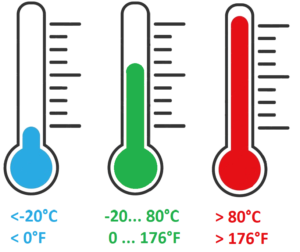

The entire range is designed to operate at temperatures ranging from -20°C to +80°C. (0°F to 176°F)

It is possible to use certain telescopic slides for temperatures ranging from -50°C to +250°C (-50°F to 500°F), after adaptation in the factory.

Heavy use or vibration:

In case of heavy use or vibration, we recommend the use of steel slides with hardening treatment.

6 – What are the uses for the industrial telescopic slide?

Our industrial slides are designed for heavy loads, in this case industrial equipment that requires the use of strong and reinforced slides. Thanks to their strength, slide can withstand the most extreme weather conditions.

they arefound in the following sectors :

– Railways, as our industrial sliders can withstand vibrations and heavy use

– Industrial production, especially in protective enclosures and for industrial machinery. Telescopic slides protect the operator and the machine system against the risk of chips and liquids,

– In the automotive or truck industry, especially for the interior fittings of special vehicles,

– In the electrical and electronic sector, especially in civil or military electronic racks or for medical equipment,

– …

7 – Any question?

please feel free to contact us; we’ll be more than happy to help.