A brief history of translation solutions for trains:

Back in 1972, a well-known French train manufacturer was looking for a partner to design and manufacture high-performance travel solutions to support 450kg battery boxes under train carriages.

At the cutting edge of technology, not only did the load constraints have to be met, but there was also a demand for over-extension to access the offset drawers under the train carbody.

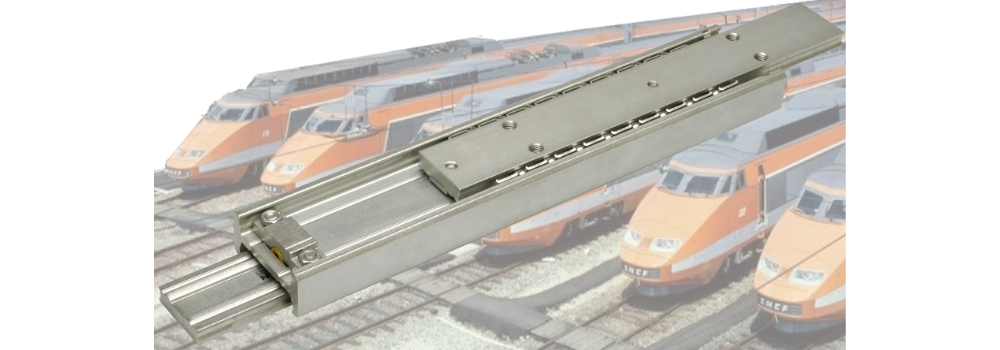

The CHAMBRELAN teams, after working tirelessly on the project, designed and produced the E1902 heavy-duty steel telescopic slide.

This was the start of the “I” slide range, which now includes around ten different models with folded lengths of up to 2 metres and extensions of up to 3 metres!

The story continues today:

With its extreme conditions (vibrations, intensive use, etc.), the rail sector requires robust, long-lasting equipment.

CHAMBRELAN has developed a range specially designed for the demanding environments imposed by the rail industry.

1 – Translation solutions for trains, high-speed trains and trams

CHAMBRELAN offers runners made from high-performance materials, namely steel, for professionals in the rolling stock industry. Cold-drawn, they offer greater resistance to heavy loads, even under strong vibrations.

To meet the needs of the sector, CHAMBRELAN has fitted its telescopic slides with reinforcing balls on the back of the slide elements. This innovation provides increased resistance to the torsional stresses of parts under load. This system optimises the load capacity of linear guides, while making it possible to mount telescopic rails flat.

Today, some of our slides open synchronously to reduce the forces required to set them in motion.

All our products are supplied with high-quality standard anti-corrosion protection (minimum of 400 hours resistance to salt spray test as standard up to over 1000 hours). Steel models are coated with an average 12 micron thick white zinc coating. Stainless steel models are supplied electro-polished, making them even more resistant to oxidation.

To meet the requirements of our customers and partners in the rail industry, our slides are tested on our test bench directly from our production plant.

2 – Advantages of telescopic slides for rolling stock

In the context of the rail industry, CHAMBRELAN translation solutions offer a number of advantages for trains:

A – Quick access and space saving

Thanks to these sliding systems, it is easier to assemble and dismantle certain modules, a significant advantage in the event of an emergency and for maintenance productivity.

CHAMBRELAN telescopic slides are very compact, which also saves space, particularly for telescopic steps, and reduces the weight carried and therefore the carbon footprint.

The runners also make it easier to use certain elements, such as the opening and closing of WC doors. The doors are mounted on curved rails that save considerable space and enhance the customer experience.

B – Discretion and ease of use

With CHAMBRELAN slides, sliding is smooth and continuous. All thanks to a special lubrication system. When they leave the factory, steel telescopic slides are already lubricated with a high-pressure bearing grease and specific grease for stainless steel models. However, it is possible to request specific lubrication such as high-temperature grease.

Special greases are available for extreme applications: frost resistance, electrical conduction, noise reduction, etc.

C – Safety system

Our telescopic slides are sold with stops sized to withstand repeated handling at the rated load. To hold the modules in the open or closed position, you can request an optional mechanical locking system, either internal to the slide (telescopic slides with locks) or external (ergonomic handle with lock).

For telescopic slides with a locking system, the lock engages naturally when the telescopic slide is fully opened or closed. Manual action is required to unlock the locking system.

There are three options for locking:

- open lock: simply press the lock in the open position to fold the slide.

- lock closed: press the lock to unfold the module.

- lock closed and open: keeps the module in the open or closed position, and simply activates the lock to extend or retract the moving part of the slide.

D – Surface treatment

Although all models of CHAMBRELAN telescopic slides are supplied with a standard anti-corrosion treatment, more corrosion-resistant treatments can be requested as an option. Steel slides can be nitrided. This operation will optimise their lifespan in the event of intensive use and reinforce their resistance to matting if they are exposed to strong vibrations.

3 – Main applications for translation solutions for trains

For over 60 years, CHAMBRELAN has been designing telescopic slides for all industrial applications. CHAMBRELAN linear guides are available in partial, total or super-extension versions. These ultra-resistant telescopic slides have a maximum load capacity ranging from 50 kg to 1500 kg. They are generally used on passenger access doors, footboards and seat adjustment systems. They can also be found under trains, in battery boxes, etc.

A – Battery containers

Each wagon is fitted with a battery box to power the various devices on the trains. To improve maintenance, these battery boxes, also known as B-tray, are mounted on telescopic slides. This is why CHAMBRELAN has developed specific telescopic ball bearing slides to facilitate the removal of the battery boxes.

B – Steps

It is important that these components are robust and reliable, as they contribute to the overall safety of the railway system. Safety standards in the rail industry often require durable materials and a solid design to prevent malfunctioning during train operation.

Partial extension telescopic slides are mechanisms that allow progressive movement of elements, such as footboards, by providing stable support and controlled extension. This can be crucial in ensuring the safety of passengers and railway staff when boarding and disembarking.

Guide rails combined with CHAMBRELAN roller runners can also ensure the smooth operation of steps and gaps by allowing higher operating speeds and quieter operation.

C – Sliding doors

1. Passenger access doors

Train doors are essential to allow passengers to enter and exit train carriages safely. These doors are usually located on the side of the carriages and can be equipped with various locking and security mechanisms. Train access doors must be designed to withstand varying weather conditions, ensure fast and reliable opening and closing, and comply with railway safety standards.

2. Interior doors

Interior train doors separate the different compartments or spaces inside a carriage. They are designed to ensure passenger privacy and to facilitate movement inside the train. The doors can be sliding to save space. In the case of toilet cubicles, the doors can be curved, requiring the use of the CHAMBRELAN curved rail.

3. PSD – Plateform screen door

Plateform Screen Doors are devices installed on the platforms of train stations to ensure passenger safety during boarding and alighting. These screen doors are usually aligned with the carriage doors. They open and close in synchronisation with the train doors, creating a physical barrier between the platform and the rails. This reduces the risk of accidental falls and also prevents unauthorised access to the rails. Screen Door Platforms help to improve the overall safety of railway stations by minimising potential hazards associated with platforms.

Numerous cycles = nitrided rail for several million repetitions.

4 – Some models of translation solutions for trains and trams

E1700

A full-extension telescopic slide for heavy loads, this nitrided model offers great strength and a long service life. Featuring magnetic synchronisation, the forces required to open its telescopic slides are low.

Its length can range from 500 mm to 2,000 mm.

Its maximum load capacity is 550 kg per pair of telescopic slides.

E70 + E70RS

Master track + slave track for greater tolerance during assembly. 3 or 5 stainless steel rollers as standard. Self-gripping stainless steel rollers for high operating speeds, reduced maintenance and less risk of jamming.

Its length can range from 250 mm to 2,000 mm.

Maximum load capacity is 450 kg per roller.

RA774M

This reinforced, synchronised super-extension slide is made of galvanised steel with ball-bearing reinforcements.

It is highly resistant to extreme conditions.

Its 4 elements can support heavy loads.

On edge, this model can carry up to 228 kg per pair, compared with 80 kg flat.

With a length of 2 metres, it can be extended by 3 metres, giving a total unfolded length of 5 metres!

ER28-B28R3 and ER28-B28R5

This standard product has several possible roller shoes (3 or 5 rollers per shoe). The standard version does not have a stop to allow the mobile element to be removed.

Its high load-bearing capacity (up to 300 kg per pad) and small footprint mean it can be perfectly integrated into your applications.

With a surface treatment to harden the raceways (nitriding), this rail can be used intensively for several million cycles.