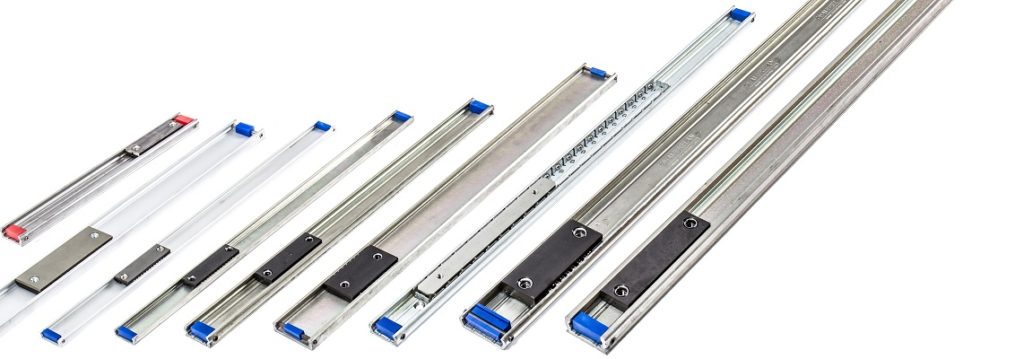

4 steps to select your linear guide rail ? You also call it guide, linear guide, sliding rail or telescopic rail but you don’t know which one to choose? Morevover CHAMBRELAN offers you 30 references, 3 different materials and a huge choice of lengths, runners, and options depending on the use…

First of all, let’s define what a linear rail is:

A linear rail consists of a runner, with recirculation ball bearing or rollers, which slides inside a rail.

This 4 steps guide help you in selecting THE linear guide you need!

We also invite you to discover on our Youtube channel a video presentation of our different linear guide rails

Contents :

- Rail Lengths and travel

- Ball bearing or roller runners and load capacity

- Materials

- Options

1- Rail length and stroke

First of all you need to determine the length of the guide rail you need for your installation.

-

- You know the travel length; this is your first piece of information,

- Depending on the size or mass of the device to be moved, you can guide it with 1, 2 or more runners per rail. The space used by all the runners must be taken into account,

- The rails are equipped with end stops, so this dimension must also be taken into account.

Thus, the dimension of your linear guide rail will be:

Dimension used by the linear bearing runners

+ Stroke Length

+ Dimensions of the end stops

= Minimum overall length of your guide rail

We offer several types of lengths:

Just ask us and we will provide you with the linear guide you need! CHAMBRELAN offers you:

-

- Standard Linear Rails, to reduce manufacturing time:With lengths in steps of 50 to 100mm. We limit the maximum length to 2 meters for logistic reasons. These rails are delivered:

- pre-equipped with end stops,

- undrilled; you will only need to counter-drill them during assembly.

- IN STOCK Guide Rails in 4 predefined lengths immediately available (stoppers included):

- 500 mm

- 1000 mm

- 1500 mm

- 2000 mm

- Specific Guide Rails:

- Standard Linear Rails, to reduce manufacturing time:With lengths in steps of 50 to 100mm. We limit the maximum length to 2 meters for logistic reasons. These rails are delivered:

You wish to integrate a rail of a specific length into your project or to receive your rails pre-drilled or with an option? Once again, we have the solution! As a manufacturer, CHAMBRELAN designs for you the ideal sliding rail for your installation, to the millimetre! No more need to cut it in your workshop, we do it for you! A drilling, a lubrication or a specific treatment is necessary? We can do it for you! We invite you to discover our options at the end of this article!

Linear rail with ball bearing runner

2 – Ball bearing or roller runners and load

Once you have chosen the length of your linear guide rail, comes the question of the runner.

The available space and above all the mass of your device will be decisive in the choice of the ball bearing runner. The load we give is indicated PER RUNNER: thus mounting 2 sliders doubles the load capacity. And we have in our range recirculating ball bearing slides that can support 600 kilos per runner!

The load defines the runner which in turns defines the rail!

We manufacture our guides based on 2 technology: Ball bearing runner or roller runner What are the differences between these two types?

-

- Ball bearing runner :

It is the most popular of our range and is perfectly adapted to industrial environments. Strong and compact, these linear rails with recirculating ball bearing runner can support hundreds of kilos, like the E98/G12 ultra-heavy-duty steel linear rail.

Recirculating Ball Bearing Runner

-

- Roller runners:

We propose two references of roller skid supporting medium to heavy loads: one full stainless steel guide rail, the other in steel with plastic coated rollers.

These two types of runner can be inserted in several linear guide rails (in steel, aluminium or stainless steel). They slide smoothly and quietly in the rail, more than the recirculating bearing runners. They are appreciated for installations on sliding doors, machine housings or protective hoods. They are adjustable, in so far as the middle runner is on an adjustable excentric screw. This allow to adjust the play and the movment smoothness.

Although a flat mounting is possible and less penalizing than for a telescopic slide, we always recommend an major axis mounting! Indeed, for the same reference, the load can be divided by two depending on the type of mounting:

-

- steel linear guide E46/G52: major axis mounting: 250 kg per runner

- steel Linear guide E46/G52: bottom mounted: 125 kg per runner

3- Material :

As for our range of telescopic slides, we offer three different materials depending on your project:

Although steel is the most common material, sometimes it is necessary to use stainless steel for outdoor environments or clean rooms. Although steel is the most common material, sometimes it is necessary to use stainless steel for outdoor environments or clean rooms.

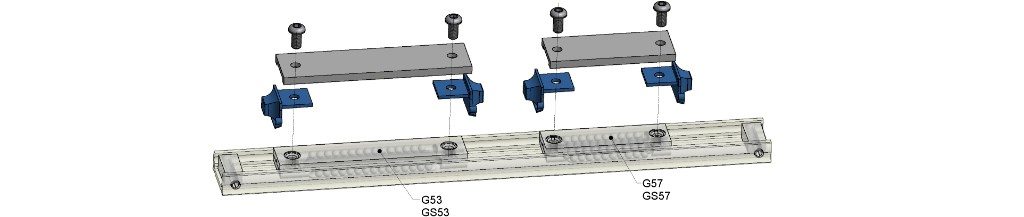

5 – Options :

By following these different steps, you have just determined the standard guide rail that you need to meet your needs! How about going a little further? Indeed, CHAMBRELAN offers several options to help you build your project!

-

- Rail drilling:All of our standard linear rails are manufactured and delivered without drilling. Upon request, for an additional price, we can offer bespoke drilling scheme according to your drawing.

Our runners are threaded. These drillings cannot be modified. - Greasing:the runners are greased in the factory (high pressure bearing grease or white grease). But you can ask for a specific grease:

- food compatible,

- high temperature

- without teflon

- or even a no greasing (unrecommended).

- Specific surface treatment of the rail:increased corrosion resistance,

Additional hardness … - wiper kit :for an optimization of the movement of the ball bearing skid, this wiper kit installed on the runner allows to push out of the raceways, impurities and dust.

- Rail drilling:All of our standard linear rails are manufactured and delivered without drilling. Upon request, for an additional price, we can offer bespoke drilling scheme according to your drawing.

Do not hesitate to share your projects with us!

CHAMBRELAN offers you the most adapted rail of your project! To help you to identify the right reference do not hesitate to contact us to discuss it!